FAIR MANUFACTURING BALE PROCESSORS FOR SALE

Bale Processor & Straw Blower

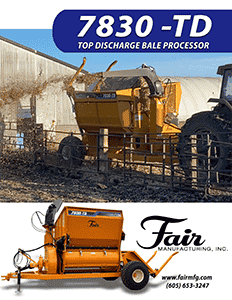

7830-TD

The 7830-TD Bale Processor is our Top Discharge round hay bale processor & straw blower with casting ability up to 100 feet in all directions. This round bale processor is the best machine for bedding pens and buildings, stockpile grinding and land reclamation projects.

In-cab controls are added to save time and energy - with only one tractor remote required. Our design has few moving parts with two oil bath chain drives and no belts that slip under high loads. The powerful fan is mounted on the same axis as the auger enabling it to handle large masses of wet hay without plugging. It also greatly simplifies the design translating to low maintenance and excellent longevity.

Our 7830-TD hay processor will shred hay bales and cast material in the worst conditions.

- Simple Design with Fewer Plug Points and Less Moving Parts

- Easy Maintenance Access to Blower, Auger, and Rotor

- Robust Oil Bath Chain Drives - No Belts!

- Hydraulic Slug Bars

- In-Cab Control Panel

- Heavy Duty Conveyor

- This round hay bale shredder has a patented rotor design

- Exclusive Bale Ejection Door

- Easy Replacement Liners

TOUGHEST EQUIPMENT ON THE MARKET.

JOIN OUR MAILING LIST

Sign up to receive our latest innovations & products

FAIR MANUFACTURING builds equipment you trust in the worst field conditions. We know you have a reputation to uphold and a community who relies on you. Our products have been tested, tried and abused in the field for over 50 years.

The hydraulically controlled spout casts up to 100 feet on either side of the processor. The extended length deflector gives the operator complete control over the discharge location when bedding tight pens or barns.

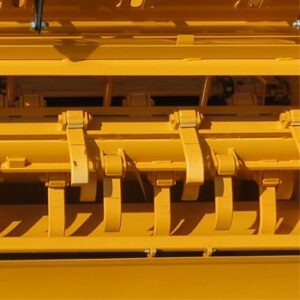

The hydraulically controlled spout casts up to 100 feet on either side of the processor. The extended length deflector gives the operator complete control over the discharge location when bedding tight pens or barns. The flails on the rotor pass through removable stationary knives to chop hay for a more palatable consumption and a finer cut. (standard on all models) 5/8”x 2” flails are heaviest on the market.

The flails on the rotor pass through removable stationary knives to chop hay for a more palatable consumption and a finer cut. (standard on all models) 5/8”x 2” flails are heaviest on the market. The hydraulic slug bars allow the operator to decrease knife exposure as the bale gets processed down to a smaller core for complete control of discharge volume. (standard on all models)

The hydraulic slug bars allow the operator to decrease knife exposure as the bale gets processed down to a smaller core for complete control of discharge volume. (standard on all models) Only one tractor remote is required making hooking up quick and easy. All electric controls can be mechanically overridden.

Only one tractor remote is required making hooking up quick and easy. All electric controls can be mechanically overridden. The patented parallel running bars create separation between the twine and rotor, allowing the operator adequate space to insert a cutting tool for easy twine removal.

The patented parallel running bars create separation between the twine and rotor, allowing the operator adequate space to insert a cutting tool for easy twine removal.